Sintered NdFeB Magnets

Keywords:

Classification:

Sintered NdFeB Magnets

- Home

- Detail

- Properties

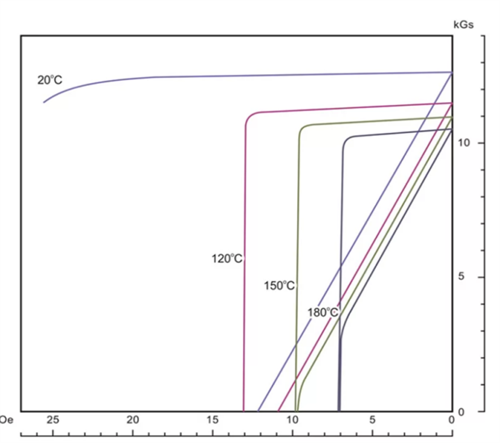

- Demagnetization Curve

- Grain Boundary Diffusion

- Directions of Magnetization

- Shape Type

- Coating Type

-

- Commodity name: Sintered NdFeB Magnets

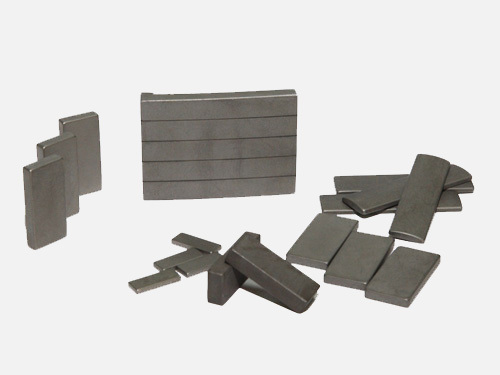

NdFeB magnets, also known as the "King of Permanent Magnets", is one of the most significant members of the rare earth magnet family. Sintered NdFeB is a rare earth permanent magnet material produced by powder metallurgy. RUIJIN-MAG's bulk neodymium magnets for sale can be customized varying from size, shape, magnetic direction to coating according to specific needs and applications by customers.

Product introduction

Sintered NdFeB Magnets are the strongest permanent magnets, possessing high magnetic energy and maximum energy product. Sintered NdFeB magnets are composed of rare earth metal neodymium, iron, and boron, and are made through a sintering process. These sintered NdFeB magnets are widely used in various electronic devices such as hard disk drives, speakers, and electric motors.

Sintered NdFeB Magnets

These are the most powerful commercialized permanent magnets available today, with maximum energy product ranging from series of N, M, H, SH, UH, EH to AH.Sintered NdFeB Magnetic Properties

Item Grade Remanence

(Br)Remanent magnetic coercivity

(Hcb)Endowed with coercion and stubbornness

(Hcj)Maximum magnetic energy product

(BH)maxTemperature kGs T kOe kA/m kOe kA/m MGOe KJ/m³ L/D≥0.5(℃) N N35 11.7-12.2 1.17-1.22 >10.9 ≥868 ≥12 ≥955 33-36 263-287 ≤80 N38 12.2-12.5 1.22-1.25 >11.3 ≥899 >12 >955 36-39 287-310 ≤80 N40 12.5-12.8 1.25-1.28 ≥11.4 ≥907 ≥12 ≥955 38-41 302-326 ≤80 N42 12.8-13.2 1.28-1.32 ≥11.5 ≥915 ≥12 ≥955 40-43 318-342 ≤80 N45 13.2-13.8 1.32-1.38 ≥11.6 ≥923 ≥12 ≥955 43-46 342-366 ≤80 N48 13.8-14.2 1.38-1.42 >11.6 ≥923 ≥12 >955 46-49 366-390 ≤80 N50 14.0-14.5 1.40-1.45 ≥12.0 ≥955 ≥11 >876 48-51 382-406 ≤80 N52 14.3-14.8 1.43-1.48 ≥11.0 ≥876 ≥11 ≥876 50-53 398-422 ≤80 N54 14.5-15.0 1.45-1.50 ≥11.0 ≥876 >11 ≥876 52-55 414-438 ≤70 M 35M 11.7-12.2 1.17-1.22 ≥10.9 ≥868 ≥14 >1114 33-36 263-287 ≤100 38M 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥14 ≥1114 36-39 287-310 ≤100 40M 12.5-12.8 1.25-1.28 ≥11.6 ≥923 ≥14 ≥1114 38-41 302-326 ≤100 42M 12.8-13.2 1.28-1.32 >12.0 ≥955 ≥14 >1114 40-43 318-342 <100 45A 13.2-13.8 1.32-1.38 >12.5 ≥995 ≥14 >1114 43-46 342-366 <100 48M 13.7-14.3 1.37-1.43 >12.9 >1027 ≥14 >1114 46-49 366-390 <100 50M 14.0-14.5 1.40-1.45 ≥13.0 ≥1033 ≥14 ≥1114 48-51 382-406 <100 52M 14.3-14.8 1.43-1.48 ≥13.1 ≥1043 ≥14 ≥1114 50-53 398-422 <100 H 35H 11.7-12.2 1.17-1.22 ≥10.9 ≥868 ≥17 ≥1353 33-36 263-287 ≤120 38H 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥17 ≥1353 36-39 287-310 ≤120 40H 12.5-12.8 1.25-1.28 >11.6 ≥923 ≥17 >1353 38-41 302-326 <120 42H 12.8-13.2 1.28-1.32 >12.0 ≥955 >17 >1353 40-43 318-342 <120 45H 13.2-13.7 1.32-1.37 ≥12.3 ≥973 ≥17 ≥1353 43-46 342-366 ≤120 48H 13.7-14.2 1.37-1.42 ≥12.5 ≥995 ≥17 >1353 46-49 366-390 <120 50H 14.0-14.5 1.40-1.45 ≥12.6 ≥1003 ≥17 ≥1353 48-51 382-406 ≤120 SH 35SH 11.7-12.2 1.17-1.22 ≥11.0 >876 ≥20 ≥1592 33-36 263-287 <150 38SH 12.2-12.5 1.22-1.25 ≥11.4 >907 ≥20 ≥1592 36-39 287-310 <150 40SH 12.5-12.8 1.25-1.28 >11.8 ≥939 ≥20 >1592 38-41 302-326 <150 42SH 12.8-13.2 1.28-1.32 ≥12.1 ≥963 ≥20 >1592 40-43 318-342 ≤150 45SH 13.2-13.8 1.32-1.38 ≥12.3 ≥979 ≥20 >1592 43-46 342-366 ≤150 48SH 13.7-14.3 1.37-1.43 ≥12.7 ≥1011 ≥20 >1592 46-49 366-390 <150 UH 28UH 10.4-10.8 1.04-1.08 ≥9.6 ≥764 ≥25 ≥1990 26-29 207-231 ≤180 30UH 10.8-11.3 1.08-1.13 ≥10.2 ≥812 >25 ≥1990 28-31 223-247 <180 33UH 11.3-11.7 1.13-1.17 ≥10.7 >852 ≥25 ≥1990 31-34 247-271 <180 35UH 11.7-12.2 1.17-1.22 >10.8 >860 ≥25 >1990 33-36 263-287 <180 38UH 12.2-12.5 1.22-1.25 ≥11.3 ≥899 >25 >1990 36-39 287-310 ≤180 40UH 12.5-12.8 1.25-1.28 ≥11.8 ≥939 ≥25 ≥1990 38-41 302-326 ≤180 42UH 12.8-13.2 1.28-1.32 ≥12.1 ≥963 ≥25 ≥1990 40-43 318-342 ≤180 45UH 13.2-13.8 1.32-1.38 ≥12.3 ≥979 ≥25 ≥1990 43-46 342-366 ≤180 EH 28EH 10.4-10.8 1.04-1.108 >9.8 ≥780 ≥30 ≥2388 26-29 207-231 <200 30EH 10.8-11.3 1.08-1.13 ≥10.2 >812 ≥30 ≥2388 28-31 223-247 <200 33EH 11.3-11.7 1.13-1.17 >10.5 ≥836 ≥30 >2388 31-34 247-271 <200 35EH 11.7-12.2 1.17-1.22 ≥11.0 ≥876 >30 >2388 33-36 263-287 <200 38EH 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥30 >2388 36-39 287-310 ≤200 40EH 12.5-12.8 1.25-1.28 ≥11.6 ≥923 ≥30 ≥2388 38-41 302-326 ≤200 42EH 12.8-13.2 1.28-1.32 ≥11.7 ≥931 >30 ≥2388 40-43 318-342 ≤200 AH 28AH 10.4-10.8 1.04-1.08 ≥9.9 >787 >33 ≥2624 26-29 207-231 <230 30AH 10.8-11.3 1.08-1.13 ≥10.3 >819 ≥33 ≥2624 28-31 223-247 <230 33AH 11.3-11.7 1.13-1.17 >10.6 ≥843 >33 >2624 31-34 247-271 <230 35AH 11.7-12.2 1.17-1.22 ≥11.0 ≥876 ≥33 >2624 33-36 263-287 <230 38AH 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥33 ≥2624 36-39 287-310 ≤230 40AH 12.5-12.8 1.25-1.28 ≥11.6 ≥923 ≥33 ≥2624 38-41 302-326 <230 NOTE:

■ the above-mentioned data ot maanetic barameters and phvsical propertles are aiven at room temperature

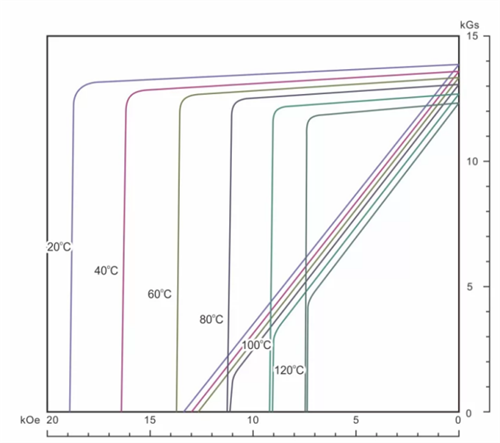

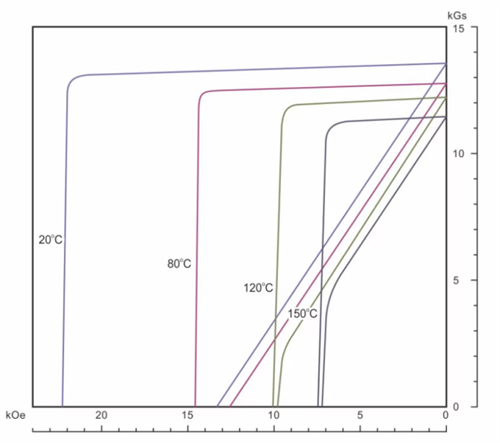

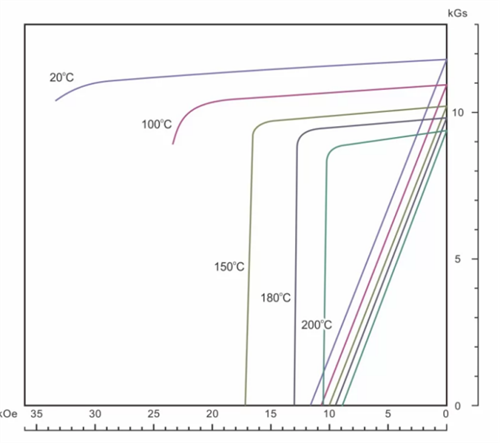

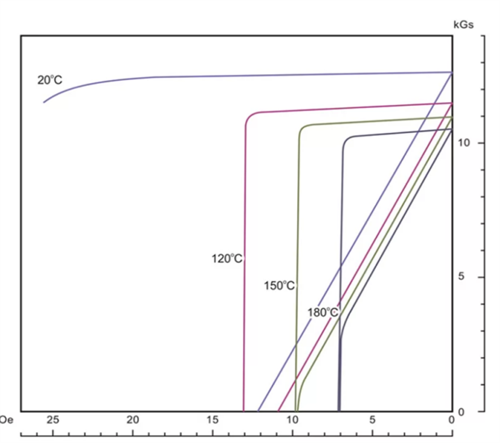

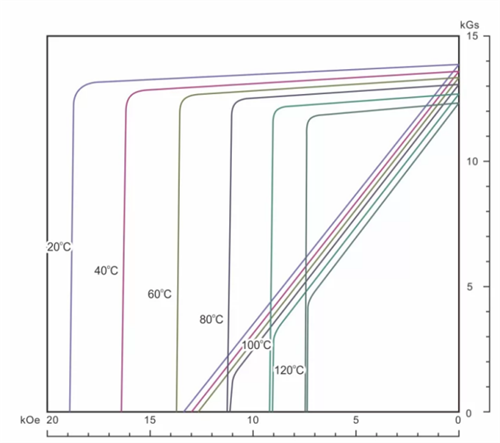

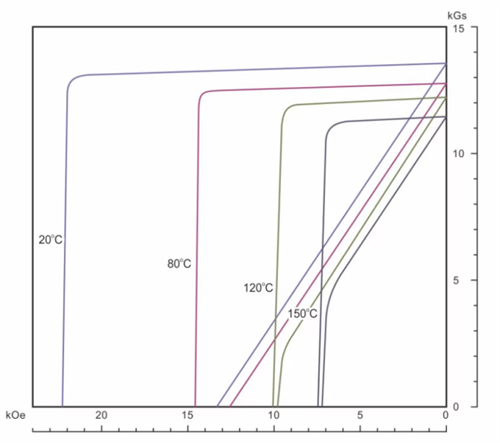

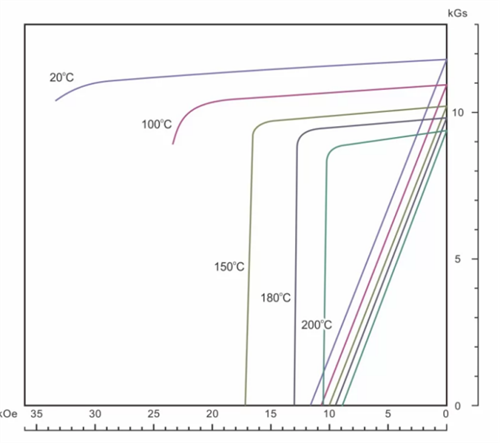

■ The maximum working temperature of magnet is changeable due to length-diameter ratio, thickness and environment factors.Sintered NdFeB Demagnetization Curve

48H 45SH

35AH 38UH Sintered NdFeB Magnets Grain Boundary Diffusion

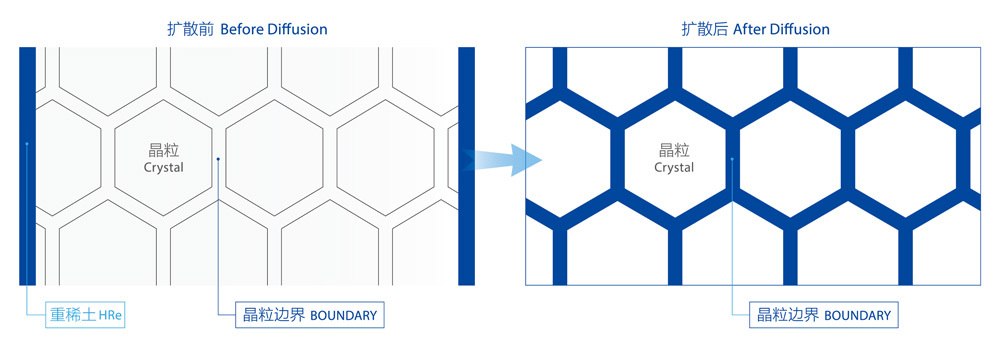

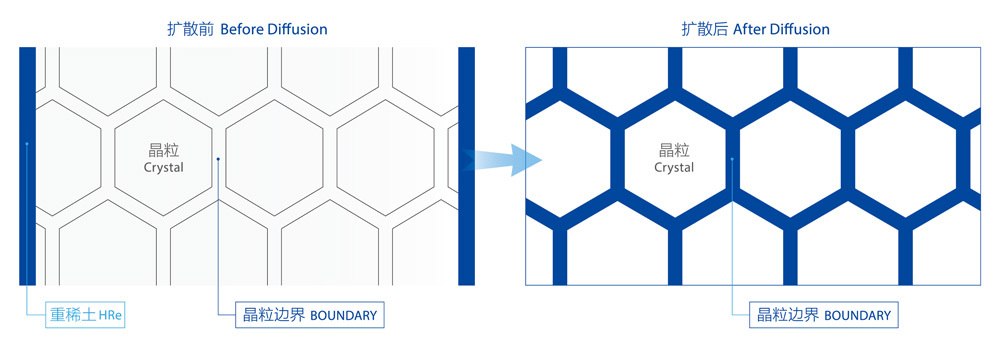

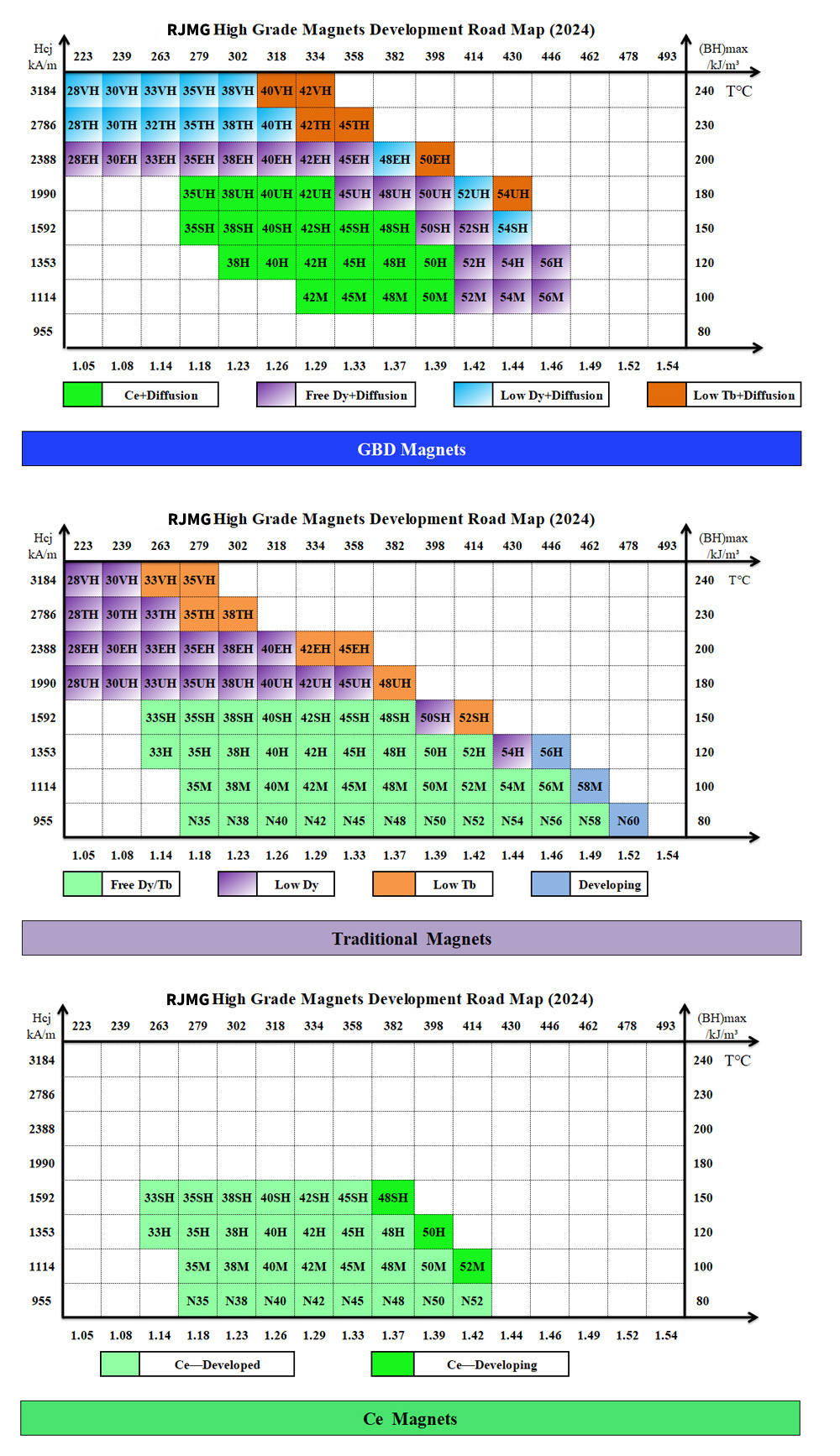

Through PVD, CVD or printing technology, alloys such as DY, Tb, and Pr are diffused from the surface of the magnet to the inside of the magnet through heat at about 900°C, and a high coercivity shell is formed on the surface of the grain to greatly improve the coercivity of the magnet without reducing remanence.

Magnetic Properties of GBD Magnets Grade Remanence,Br mT or kGs Coercivity, Hcb kA/m or kOe Intrinsic Coercivity, H Maximum Energy Product, Max Working Temp TW(°C ) cJ kA/m or kOe (BH)max kJ/m3 or MGOe G55H 1440-1480(14.4-14.8) ≥1061(≥13.3) ≥1353(≥17) 398-422 (53-56) 120 G52H 1410-1470(14.1-14.7) ≥1050(≥13.2) ≥1353(≥17) 398-422 (50-53) 120 G55SH 1440-1480(14.4-14.8) ≥1050(≥13.3) ≥1592(≥20) 398-422 (53-56) 150 G52SH 1430-1450(14.3-14.5) ≥1050(≥13.2) ≥1592(≥20) 406-430 (51-54) 150 G5OSH 1400-1450(14.0-14.5) ≥1035(≥13.0) ≥1592(≥20) 382-406 (48-51) 150 G48SH 1370-1430(13.7-14.3) ≥1035(≥13.0) ≥1592(≥20) 366-390 (46-49) 150 G45SH 1320-1370(13.2-13.7) ≥1003(≥12.6) ≥1592(≥20) 342-366 (43-46) 150 G52UH 1410-1470(14.1-14.6) ≥1050(≥13.2) ≥1990(≥25) 398-422 (50-53) 180 G50UH 1400-1450(14.0-14.5) ≥1035(≥13.0) ≥1990(≥25) 382-406 (48-51) 180 G48UH 1370-1430(13.7-14.3) ≥1035(≥13.0) ≥1990(≥25) 366-390 (46-49) 180 G45UH 1300-1360(13.0-13.6) ≥1003(≥12.6) ≥1990(≥25) 342-366 (43-46) 180 G42UH 1280-1340(12.8-13.4) ≥907(≥11.4) ≥1990(≥25) 318-342 (40-43) 180 G40UH 1260-1310(12.6-13.1) ≥907(≥11.4) ≥1990(≥25) 302-326 (38-41) 180 G50EH 1400-1450(14.0-14.5) ≥1035(≥13.0) ≥2388(≥30) 382-406 (48-51) 200 G48EH 1370-1430(13.7-14.3) ≥1035(≥13.0) ≥2388(≥30) 366-390 (46-49) 200 G45EH 1300-1360(13.0-13.6) ≥1003(≥12.6) ≥2388 (≥30) 342-366 (43-46) 200 G42EH 1280-1320(12.8-13.2) ≥907(≥11.4) ≥2388 (≥30) 318-342 (40-43) 200 G40EH 1260-1310(12.6-13.1) ≥907(≥11.4) ≥2388 (≥30) 302-326 (38-41) 200 G38EH 1220-1270(12.2-12.7) ≥907(≥11.4) ≥2388 (≥30) 287-310 (36-39) 200 G45AH 1300-1360(13.0-13.6) ≥1003(≥12.6) ≥2786(≥35) 342-366 (43-46) 220 G42AH 1280-1340(12.8-13.4) ≥907(≥11.4) ≥2786(≥35) 318-342 (40-43) 220 G40AH 1260-1310(12.6-13.1) ≥907(≥11.4) ≥2786(≥35) 302-326 (38-41) 220 G38AH 1220-1250(12.2-12.5) ≥907(≥11.4) ≥2786(≥35) 287-310 (36-39) 220 G35AH 1160-1230(11.6-12.3) ≥812(≥10.2) ≥2786(≥35) 263-287 (33-36) 220 Directions of Magnetization

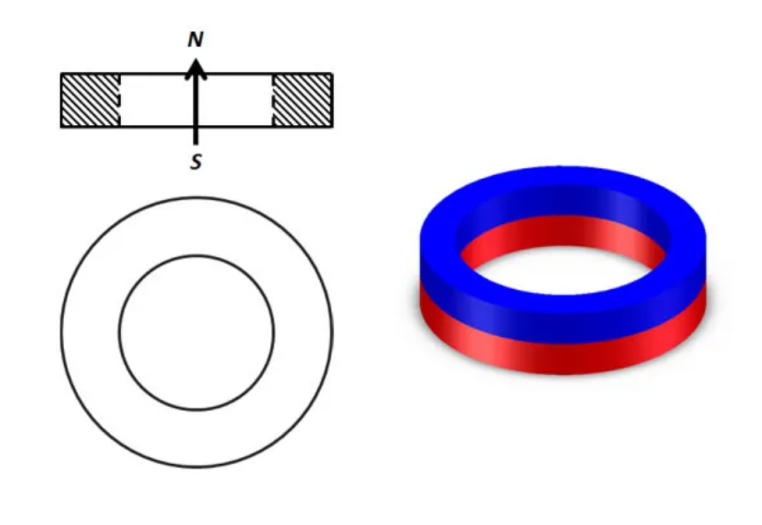

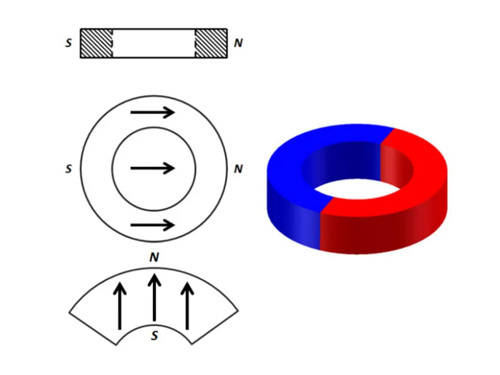

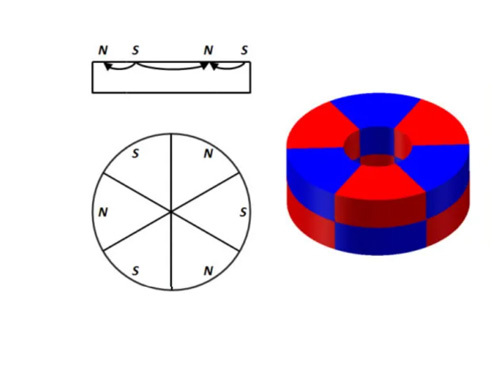

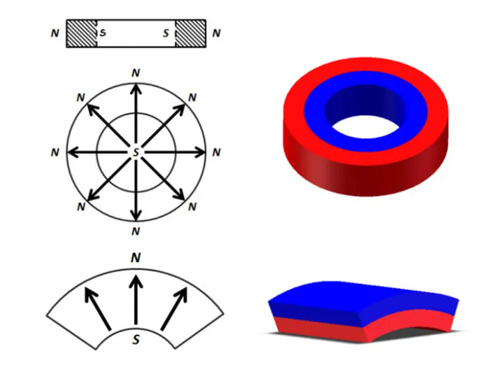

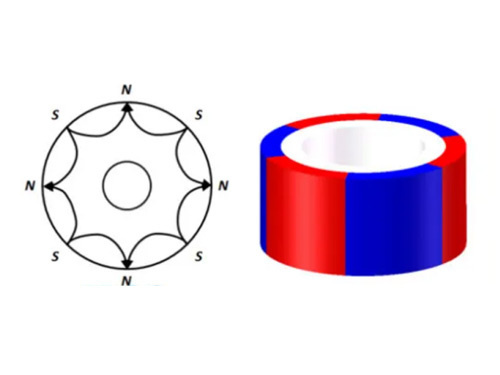

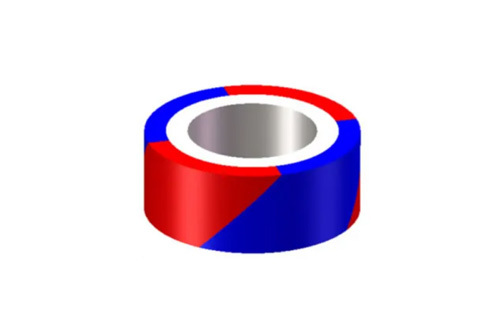

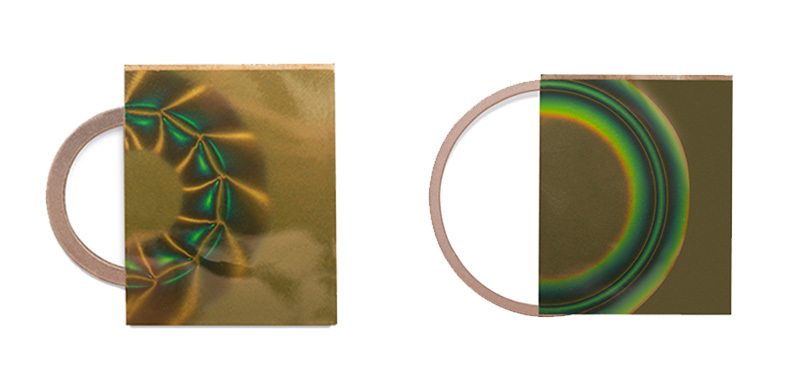

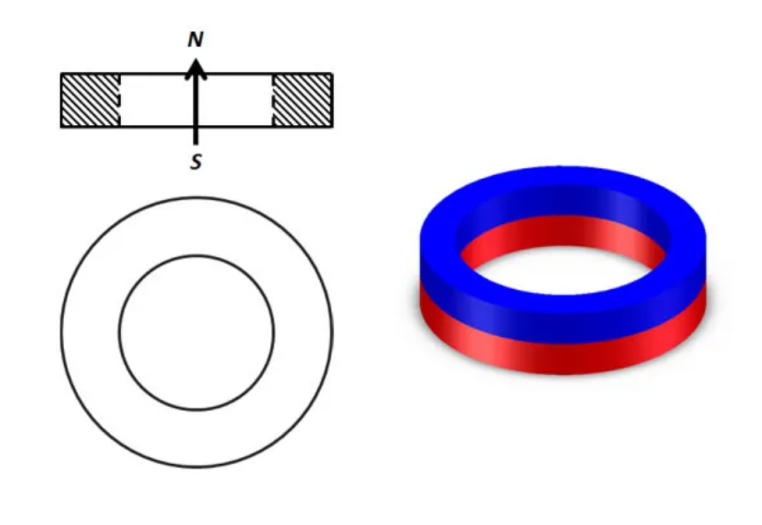

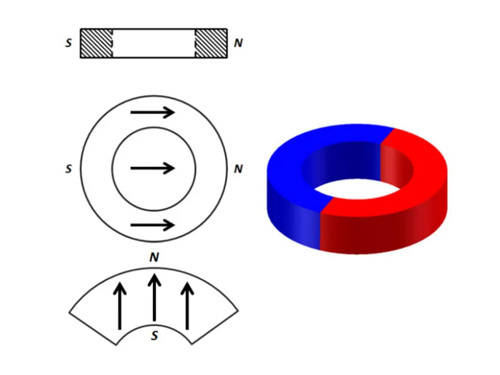

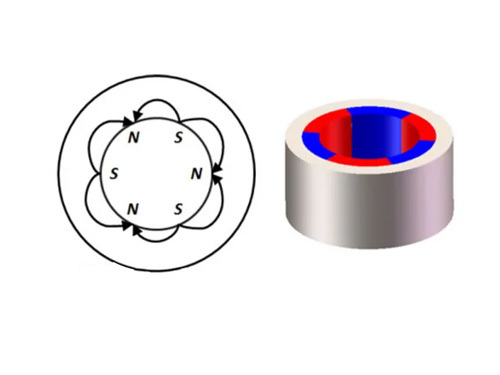

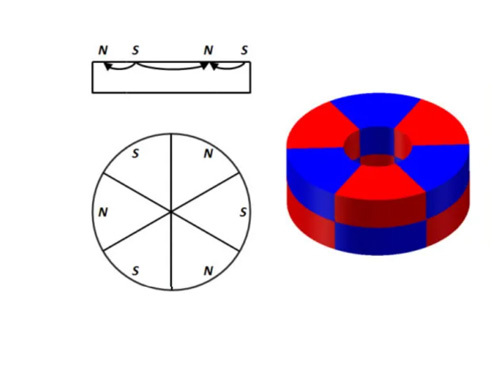

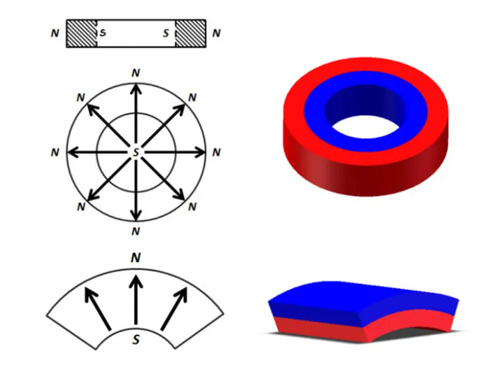

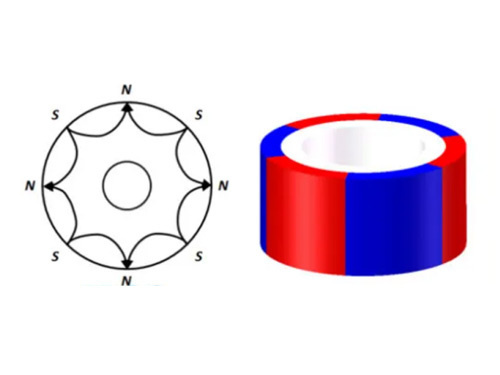

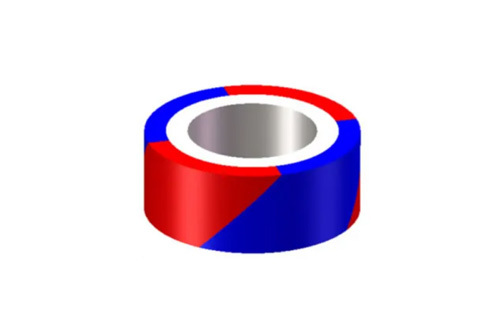

Axial magnetized Diamertrical magnetized Multi-polar magnetized in inner diameter

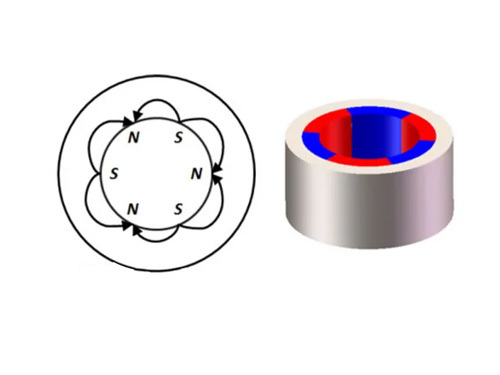

Multipolar magnetized on surface radially magnetized Multi-polar magnetized in outer diameter

Multipolar Skew magnetized Sintered NdFeB Magnets Shape Type

Available specification (Unit: mm)

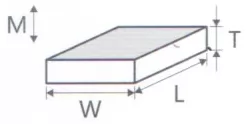

1. Block Magnet

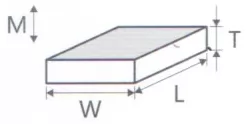

Sort Drawing Specification Recommend size Extreme size Cuboid type

L ≤150 ≤200 W ≤100 ≤100 T ≤55 ≤70 Dimension Tolerance Parallelism 0.5≤L≤10 ±0.03 0.04 10≤L≤30 ±0.05 0.06 30≤L≤50 ±0.08 0.08 L>50 ±0.1 0.1 2. Arc/C Magnet

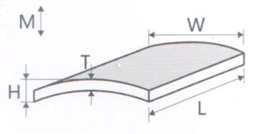

Sort Drawing Specification Recommend Size Extreme size

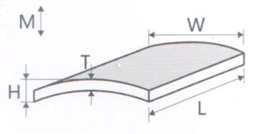

C type

L ≤150 ≤200 W ≤100 ≤100 T 2≤T≤30 1.5≤T≤50 H 3≤H≤50 3≤H≤60 Part Dimension Tolerance Thickness T≤10 ±0.04 10≤T≤30 ±0.05 Length L≤10 ±0.03 10≤L≤30 ±0.05 30≤L≤50 ±0.08 L>50 ±0.1 Chordal Length W≤50 ±0.05 W>50 ±0.06 3. Cylinder Magnet

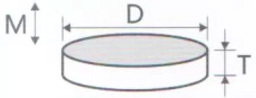

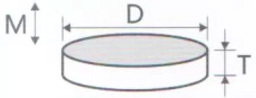

Sort Drawing Specification Recommend Size Extreme size Cylinder type

D ≤100 ≤150 T 0.5≤T≤45 0.5≤T≤60 Outter Diameter Tolerance Parallelism D≤10 ±0.02 0.03 10≤D≤30 ±0.03 0.03 D>30 ±0.04 0.04 4. Ring Magnet

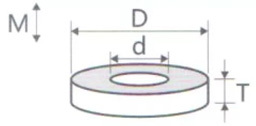

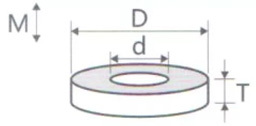

Sort Drawing Specification Ring type

D d T Inner Diameter Tolerance Coaxiality d≤10 ±0.04 0.06 10≤d≤30 ±0.05 0.06 30≤d≤50 ±0.06 0.08 d>50 ±0.08 0.1 Sintered NdFeB Magnets Coating Type

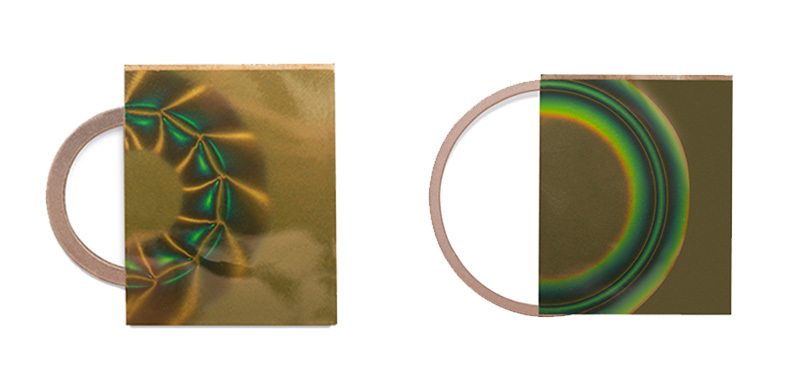

Since NdFeB magnets easily corrode, it is often coated to protect against this. Traditional coatings arePhosphating, RB, Zn, NiCuNi, ZnNi and Epoxy with other options available. Selection of a coating should be discussed early on in the design and application process.

Nicuni Au Phosphate

ZN Epoxy Black Ni Available Coatings Of Sintered NdFeB Magnets Coating Thickness Color PCT SST Characteristic Zn 4-8μm Bright Blue >24H~48H Regular Protection,

Applicable to most productsColored Zn 4-8μm Shining Color >48H~72H Excellent salt spray resistance NiCuNi 10-20μm Bright Silver >48H~72H >24H~72H Excellent humidity,

heat &salt spray resistanceElectroless Nickel 10-30μm Bright Silver >72H >96H Excellent humidity,

heat &salt spray resistanceBlack Nickel 10-20μm Bright Black >72H >48H~96H Excellenthumidity,

heat &salt spray resistanceSn 10-25μm Silver >48H >36H~72H Excellent humidity,

heat &salt spray resistanceEpoxy 10-30μm Black or Grey >72H~108H Excellent humidity,heat &salt spray

resistance,excellent adhesionPhosphated

/Passivation≤1μm Dark Grey ≤2.5H

Emerge in 3%NaCl liquorTemporary Protection Everlube 8-20μm Yellow >72H >96H Excellent salt spray resistance,

Excellent adhesionGolden 10-15μm Golden >48H >12H Good looking Notes: For different products,the salt spray test and PCT time varies with the shape and size of the product. -

Product introduction

Sintered NdFeB Magnets are the strongest permanent magnets, possessing high magnetic energy and maximum energy product. Sintered NdFeB magnets are composed of rare earth metal neodymium, iron, and boron, and are made through a sintering process. These sintered NdFeB magnets are widely used in various electronic devices such as hard disk drives, speakers, and electric motors.

Sintered NdFeB Magnets

These are the most powerful commercialized permanent magnets available today, with maximum energy product ranging from series of N, M, H, SH, UH, EH to AH. -

Sintered NdFeB Magnetic Properties

Item Grade Remanence

(Br)Remanent magnetic coercivity

(Hcb)Endowed with coercion and stubbornness

(Hcj)Maximum magnetic energy product

(BH)maxTemperature kGs T kOe kA/m kOe kA/m MGOe KJ/m³ L/D≥0.5(℃) N N35 11.7-12.2 1.17-1.22 >10.9 ≥868 ≥12 ≥955 33-36 263-287 ≤80 N38 12.2-12.5 1.22-1.25 >11.3 ≥899 >12 >955 36-39 287-310 ≤80 N40 12.5-12.8 1.25-1.28 ≥11.4 ≥907 ≥12 ≥955 38-41 302-326 ≤80 N42 12.8-13.2 1.28-1.32 ≥11.5 ≥915 ≥12 ≥955 40-43 318-342 ≤80 N45 13.2-13.8 1.32-1.38 ≥11.6 ≥923 ≥12 ≥955 43-46 342-366 ≤80 N48 13.8-14.2 1.38-1.42 >11.6 ≥923 ≥12 >955 46-49 366-390 ≤80 N50 14.0-14.5 1.40-1.45 ≥12.0 ≥955 ≥11 >876 48-51 382-406 ≤80 N52 14.3-14.8 1.43-1.48 ≥11.0 ≥876 ≥11 ≥876 50-53 398-422 ≤80 N54 14.5-15.0 1.45-1.50 ≥11.0 ≥876 >11 ≥876 52-55 414-438 ≤70 M 35M 11.7-12.2 1.17-1.22 ≥10.9 ≥868 ≥14 >1114 33-36 263-287 ≤100 38M 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥14 ≥1114 36-39 287-310 ≤100 40M 12.5-12.8 1.25-1.28 ≥11.6 ≥923 ≥14 ≥1114 38-41 302-326 ≤100 42M 12.8-13.2 1.28-1.32 >12.0 ≥955 ≥14 >1114 40-43 318-342 <100 45A 13.2-13.8 1.32-1.38 >12.5 ≥995 ≥14 >1114 43-46 342-366 <100 48M 13.7-14.3 1.37-1.43 >12.9 >1027 ≥14 >1114 46-49 366-390 <100 50M 14.0-14.5 1.40-1.45 ≥13.0 ≥1033 ≥14 ≥1114 48-51 382-406 <100 52M 14.3-14.8 1.43-1.48 ≥13.1 ≥1043 ≥14 ≥1114 50-53 398-422 <100 H 35H 11.7-12.2 1.17-1.22 ≥10.9 ≥868 ≥17 ≥1353 33-36 263-287 ≤120 38H 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥17 ≥1353 36-39 287-310 ≤120 40H 12.5-12.8 1.25-1.28 >11.6 ≥923 ≥17 >1353 38-41 302-326 <120 42H 12.8-13.2 1.28-1.32 >12.0 ≥955 >17 >1353 40-43 318-342 <120 45H 13.2-13.7 1.32-1.37 ≥12.3 ≥973 ≥17 ≥1353 43-46 342-366 ≤120 48H 13.7-14.2 1.37-1.42 ≥12.5 ≥995 ≥17 >1353 46-49 366-390 <120 50H 14.0-14.5 1.40-1.45 ≥12.6 ≥1003 ≥17 ≥1353 48-51 382-406 ≤120 SH 35SH 11.7-12.2 1.17-1.22 ≥11.0 >876 ≥20 ≥1592 33-36 263-287 <150 38SH 12.2-12.5 1.22-1.25 ≥11.4 >907 ≥20 ≥1592 36-39 287-310 <150 40SH 12.5-12.8 1.25-1.28 >11.8 ≥939 ≥20 >1592 38-41 302-326 <150 42SH 12.8-13.2 1.28-1.32 ≥12.1 ≥963 ≥20 >1592 40-43 318-342 ≤150 45SH 13.2-13.8 1.32-1.38 ≥12.3 ≥979 ≥20 >1592 43-46 342-366 ≤150 48SH 13.7-14.3 1.37-1.43 ≥12.7 ≥1011 ≥20 >1592 46-49 366-390 <150 UH 28UH 10.4-10.8 1.04-1.08 ≥9.6 ≥764 ≥25 ≥1990 26-29 207-231 ≤180 30UH 10.8-11.3 1.08-1.13 ≥10.2 ≥812 >25 ≥1990 28-31 223-247 <180 33UH 11.3-11.7 1.13-1.17 ≥10.7 >852 ≥25 ≥1990 31-34 247-271 <180 35UH 11.7-12.2 1.17-1.22 >10.8 >860 ≥25 >1990 33-36 263-287 <180 38UH 12.2-12.5 1.22-1.25 ≥11.3 ≥899 >25 >1990 36-39 287-310 ≤180 40UH 12.5-12.8 1.25-1.28 ≥11.8 ≥939 ≥25 ≥1990 38-41 302-326 ≤180 42UH 12.8-13.2 1.28-1.32 ≥12.1 ≥963 ≥25 ≥1990 40-43 318-342 ≤180 45UH 13.2-13.8 1.32-1.38 ≥12.3 ≥979 ≥25 ≥1990 43-46 342-366 ≤180 EH 28EH 10.4-10.8 1.04-1.108 >9.8 ≥780 ≥30 ≥2388 26-29 207-231 <200 30EH 10.8-11.3 1.08-1.13 ≥10.2 >812 ≥30 ≥2388 28-31 223-247 <200 33EH 11.3-11.7 1.13-1.17 >10.5 ≥836 ≥30 >2388 31-34 247-271 <200 35EH 11.7-12.2 1.17-1.22 ≥11.0 ≥876 >30 >2388 33-36 263-287 <200 38EH 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥30 >2388 36-39 287-310 ≤200 40EH 12.5-12.8 1.25-1.28 ≥11.6 ≥923 ≥30 ≥2388 38-41 302-326 ≤200 42EH 12.8-13.2 1.28-1.32 ≥11.7 ≥931 >30 ≥2388 40-43 318-342 ≤200 AH 28AH 10.4-10.8 1.04-1.08 ≥9.9 >787 >33 ≥2624 26-29 207-231 <230 30AH 10.8-11.3 1.08-1.13 ≥10.3 >819 ≥33 ≥2624 28-31 223-247 <230 33AH 11.3-11.7 1.13-1.17 >10.6 ≥843 >33 >2624 31-34 247-271 <230 35AH 11.7-12.2 1.17-1.22 ≥11.0 ≥876 ≥33 >2624 33-36 263-287 <230 38AH 12.2-12.5 1.22-1.25 ≥11.3 ≥899 ≥33 ≥2624 36-39 287-310 ≤230 40AH 12.5-12.8 1.25-1.28 ≥11.6 ≥923 ≥33 ≥2624 38-41 302-326 <230 NOTE:

■ the above-mentioned data ot maanetic barameters and phvsical propertles are aiven at room temperature

■ The maximum working temperature of magnet is changeable due to length-diameter ratio, thickness and environment factors. -

Sintered NdFeB Demagnetization Curve

48H 45SH

35AH 38UH -

Sintered NdFeB Magnets Grain Boundary Diffusion

Through PVD, CVD or printing technology, alloys such as DY, Tb, and Pr are diffused from the surface of the magnet to the inside of the magnet through heat at about 900°C, and a high coercivity shell is formed on the surface of the grain to greatly improve the coercivity of the magnet without reducing remanence.

Magnetic Properties of GBD Magnets Grade Remanence,Br mT or kGs Coercivity, Hcb kA/m or kOe Intrinsic Coercivity, H Maximum Energy Product, Max Working Temp TW(°C ) cJ kA/m or kOe (BH)max kJ/m3 or MGOe G55H 1440-1480(14.4-14.8) ≥1061(≥13.3) ≥1353(≥17) 398-422 (53-56) 120 G52H 1410-1470(14.1-14.7) ≥1050(≥13.2) ≥1353(≥17) 398-422 (50-53) 120 G55SH 1440-1480(14.4-14.8) ≥1050(≥13.3) ≥1592(≥20) 398-422 (53-56) 150 G52SH 1430-1450(14.3-14.5) ≥1050(≥13.2) ≥1592(≥20) 406-430 (51-54) 150 G5OSH 1400-1450(14.0-14.5) ≥1035(≥13.0) ≥1592(≥20) 382-406 (48-51) 150 G48SH 1370-1430(13.7-14.3) ≥1035(≥13.0) ≥1592(≥20) 366-390 (46-49) 150 G45SH 1320-1370(13.2-13.7) ≥1003(≥12.6) ≥1592(≥20) 342-366 (43-46) 150 G52UH 1410-1470(14.1-14.6) ≥1050(≥13.2) ≥1990(≥25) 398-422 (50-53) 180 G50UH 1400-1450(14.0-14.5) ≥1035(≥13.0) ≥1990(≥25) 382-406 (48-51) 180 G48UH 1370-1430(13.7-14.3) ≥1035(≥13.0) ≥1990(≥25) 366-390 (46-49) 180 G45UH 1300-1360(13.0-13.6) ≥1003(≥12.6) ≥1990(≥25) 342-366 (43-46) 180 G42UH 1280-1340(12.8-13.4) ≥907(≥11.4) ≥1990(≥25) 318-342 (40-43) 180 G40UH 1260-1310(12.6-13.1) ≥907(≥11.4) ≥1990(≥25) 302-326 (38-41) 180 G50EH 1400-1450(14.0-14.5) ≥1035(≥13.0) ≥2388(≥30) 382-406 (48-51) 200 G48EH 1370-1430(13.7-14.3) ≥1035(≥13.0) ≥2388(≥30) 366-390 (46-49) 200 G45EH 1300-1360(13.0-13.6) ≥1003(≥12.6) ≥2388 (≥30) 342-366 (43-46) 200 G42EH 1280-1320(12.8-13.2) ≥907(≥11.4) ≥2388 (≥30) 318-342 (40-43) 200 G40EH 1260-1310(12.6-13.1) ≥907(≥11.4) ≥2388 (≥30) 302-326 (38-41) 200 G38EH 1220-1270(12.2-12.7) ≥907(≥11.4) ≥2388 (≥30) 287-310 (36-39) 200 G45AH 1300-1360(13.0-13.6) ≥1003(≥12.6) ≥2786(≥35) 342-366 (43-46) 220 G42AH 1280-1340(12.8-13.4) ≥907(≥11.4) ≥2786(≥35) 318-342 (40-43) 220 G40AH 1260-1310(12.6-13.1) ≥907(≥11.4) ≥2786(≥35) 302-326 (38-41) 220 G38AH 1220-1250(12.2-12.5) ≥907(≥11.4) ≥2786(≥35) 287-310 (36-39) 220 G35AH 1160-1230(11.6-12.3) ≥812(≥10.2) ≥2786(≥35) 263-287 (33-36) 220 -

Directions of Magnetization

Axial magnetized Diamertrical magnetized Multi-polar magnetized in inner diameter

Multipolar magnetized on surface radially magnetized Multi-polar magnetized in outer diameter

Multipolar Skew magnetized -

Sintered NdFeB Magnets Shape Type

Available specification (Unit: mm)

1. Block Magnet

Sort Drawing Specification Recommend size Extreme size Cuboid type

L ≤150 ≤200 W ≤100 ≤100 T ≤55 ≤70 Dimension Tolerance Parallelism 0.5≤L≤10 ±0.03 0.04 10≤L≤30 ±0.05 0.06 30≤L≤50 ±0.08 0.08 L>50 ±0.1 0.1 2. Arc/C Magnet

Sort Drawing Specification Recommend Size Extreme size

C type

L ≤150 ≤200 W ≤100 ≤100 T 2≤T≤30 1.5≤T≤50 H 3≤H≤50 3≤H≤60 Part Dimension Tolerance Thickness T≤10 ±0.04 10≤T≤30 ±0.05 Length L≤10 ±0.03 10≤L≤30 ±0.05 30≤L≤50 ±0.08 L>50 ±0.1 Chordal Length W≤50 ±0.05 W>50 ±0.06 3. Cylinder Magnet

Sort Drawing Specification Recommend Size Extreme size Cylinder type

D ≤100 ≤150 T 0.5≤T≤45 0.5≤T≤60 Outter Diameter Tolerance Parallelism D≤10 ±0.02 0.03 10≤D≤30 ±0.03 0.03 D>30 ±0.04 0.04 4. Ring Magnet

Sort Drawing Specification Ring type

D d T Inner Diameter Tolerance Coaxiality d≤10 ±0.04 0.06 10≤d≤30 ±0.05 0.06 30≤d≤50 ±0.06 0.08 d>50 ±0.08 0.1 -

Sintered NdFeB Magnets Coating Type

Since NdFeB magnets easily corrode, it is often coated to protect against this. Traditional coatings arePhosphating, RB, Zn, NiCuNi, ZnNi and Epoxy with other options available. Selection of a coating should be discussed early on in the design and application process.

Nicuni Au Phosphate

ZN Epoxy Black Ni Available Coatings Of Sintered NdFeB Magnets Coating Thickness Color PCT SST Characteristic Zn 4-8μm Bright Blue >24H~48H Regular Protection,

Applicable to most productsColored Zn 4-8μm Shining Color >48H~72H Excellent salt spray resistance NiCuNi 10-20μm Bright Silver >48H~72H >24H~72H Excellent humidity,

heat &salt spray resistanceElectroless Nickel 10-30μm Bright Silver >72H >96H Excellent humidity,

heat &salt spray resistanceBlack Nickel 10-20μm Bright Black >72H >48H~96H Excellenthumidity,

heat &salt spray resistanceSn 10-25μm Silver >48H >36H~72H Excellent humidity,

heat &salt spray resistanceEpoxy 10-30μm Black or Grey >72H~108H Excellent humidity,heat &salt spray

resistance,excellent adhesionPhosphated

/Passivation≤1μm Dark Grey ≤2.5H

Emerge in 3%NaCl liquorTemporary Protection Everlube 8-20μm Yellow >72H >96H Excellent salt spray resistance,

Excellent adhesionGolden 10-15μm Golden >48H >12H Good looking Notes: For different products,the salt spray test and PCT time varies with the shape and size of the product.

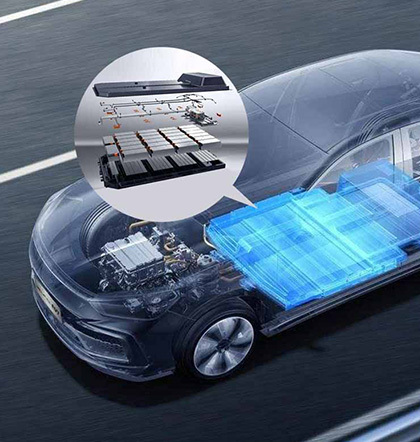

Industry applications

WHY CHOOSE US

Professional magnetic material solution provider

It is a processor and technical service provider of rare earth permanent magnet core materials in electronics, military and other industries.

Wide coverage area

Targeting the global consumer electronics market, we integrate and provide innovative products and services for brand electronics enterprises through various development models such as self operated and cooperative operations

Numerous customers

Processing and technical service providers of rare earth permanent magnet core materials in industries such as electronics and military

R&D innovation

Research and develop more intellectual property products and technologies independently for magnetic materials.

Product inquiry