Magnet Assembly

Keywords:

Classification:

Magnet Assembly

- Home

- Detail

- Halbach Assembly

- Laminated Magnet for EV Cars

- Electronic Devices

- Stator for Linear Motor

- Servo Motor Rotor Assembly

-

- Commodity name: Magnet Assembly

This refers to components that incorporate magnets, often designed to optimize the magnetic circuit for maximum performance. Magnetic components are finished or semi-finished permanent magnets or other parts composed of one or more magnetic materials. Components typically use adhesives to bond small components together to achieve certain functions that independent magnets cannot achieve. Magnetic components not only enhance the strength of the magnetic field, but also reduce eddy currents and provide good protection for fragile magnets. They can be used in a variety of applications including wind power, industrial automation, automotive industries, home appliances and etc.

Magnet Assembly

Magnet Assembly: A magnet assembly incorporates magnet and non-magnet materials with specific magnetic patterns, shapes, and field strengths designed to optimize the magnetic circuit for maximum performance. Components typically use adhesives to bond small components together to achieve certain functions that independent magnets cannot achieve. Magnetic components not only enhance the strength of the magnetic field, but also provide good protection for fragile magnets. They can be used in a variety of applications including wind power, industrial automation, automotive industries etc.

Types of our magnetic components

Halbach Assembly

Application:

Optoelectronics, robot rotor and suction components

Features:

Powerful magnetic field with a small amount of magnets

High adhesion and efficient assembly

Equipped with magnetic field simulation design technology

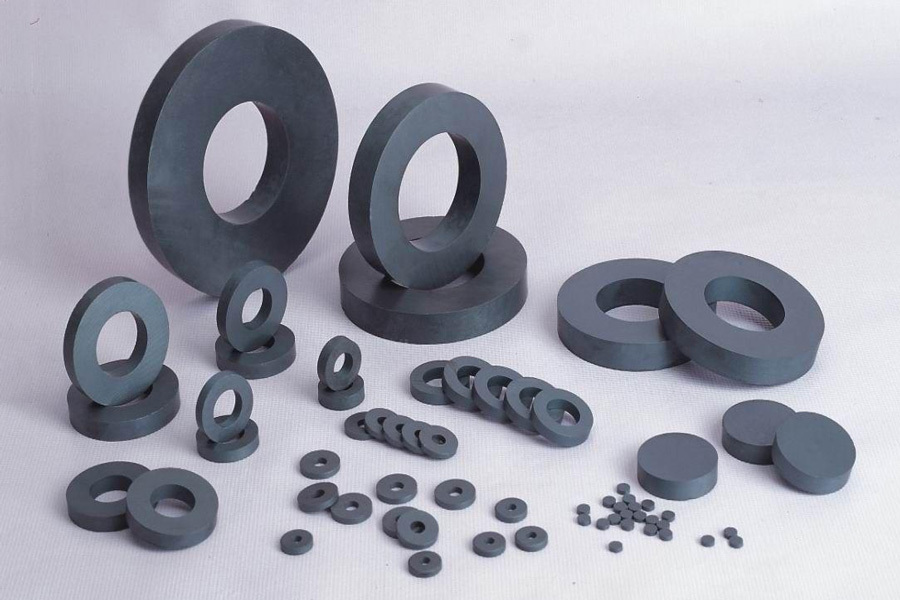

Laminated Magnet for EV Cars

Application:

Electrical vehicle drive motors, hub motors, rail transit motors

Electronic Devices

Application:

Mobile phones, audio systems, headphones, etc.

Stator for Linear Motor

Application:

Laser process equipment, IC chip manufacturing equipment, high precision machining equipment

Magnet Assembly Production Facility

* Full equipped in-house production can assure the fast prototype production.

* Sufficient outsource capability and convenient component purchasing.

* Automatic equipment, internally developed and manufactured, can assure the production capacity ramp up.

Inspection Ability

Full range of inspection of magnetic properties, mechanical features, corrosion resistance features, etc

Servo Motor Rotor Assembly

Application:

Machine tool equipment, air conditioning equipment, automation equipment

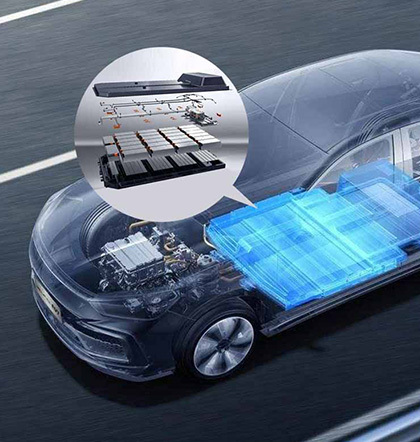

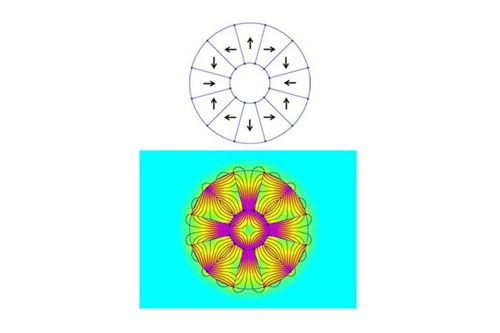

Halbach Assembly

A Halbach array is a specific arrangement of a series ofpermanent magnets. The array has a spatially rotating pattern of magnetism which cancels the field on one side but boosts it on the other. The major advantages of Halbach Arrays are that they can produce strong magnetic fields on one side whilst creating a very small stray field on the opposite side. This effect is best understood by observing the magnetic flux distribution.

• One-sided flux is useful in many applications – data security – transportation – motor design

• Halbach Arrays are inherently weight-efficient.

• Arrays provide higher fluxes than monolithic magnets of the same size.

Halbach array can be divided into ring arrays and linear arrays

Application:

• Optoelectronics, robot rotor and suction componentsFeatures:

• Powerful magnetic field with a small amount of magnets

• High adhesion and efficient assembly

• Equipped with magnetic field simulation design technology

Laminated Magnet for EV Cars

Application: Electrical vehicle drive motors, hub motors, rail transit motors

Electronic Devices

Application: Mobile phones, audio systems, headphones, etc.

Stator for Linear Motor

Application: Laser process equipment, IC chip manufacturing equipment, high precision machining equipment

Servo Motor Rotor Assembly

Application: Machine tool equipment, air conditioning equipment, automation equipment

-

Magnet Assembly

Magnet Assembly: A magnet assembly incorporates magnet and non-magnet materials with specific magnetic patterns, shapes, and field strengths designed to optimize the magnetic circuit for maximum performance. Components typically use adhesives to bond small components together to achieve certain functions that independent magnets cannot achieve. Magnetic components not only enhance the strength of the magnetic field, but also provide good protection for fragile magnets. They can be used in a variety of applications including wind power, industrial automation, automotive industries etc.

Types of our magnetic components

Halbach Assembly

Application:

Optoelectronics, robot rotor and suction components

Features:

Powerful magnetic field with a small amount of magnets

High adhesion and efficient assembly

Equipped with magnetic field simulation design technology

Laminated Magnet for EV Cars

Application:

Electrical vehicle drive motors, hub motors, rail transit motors

Electronic Devices

Application:

Mobile phones, audio systems, headphones, etc.

Stator for Linear Motor

Application:

Laser process equipment, IC chip manufacturing equipment, high precision machining equipment

Magnet Assembly Production Facility

* Full equipped in-house production can assure the fast prototype production.

* Sufficient outsource capability and convenient component purchasing.

* Automatic equipment, internally developed and manufactured, can assure the production capacity ramp up.

Inspection Ability

Full range of inspection of magnetic properties, mechanical features, corrosion resistance features, etc

Servo Motor Rotor Assembly

Application:

Machine tool equipment, air conditioning equipment, automation equipment

-

Halbach Assembly

A Halbach array is a specific arrangement of a series ofpermanent magnets. The array has a spatially rotating pattern of magnetism which cancels the field on one side but boosts it on the other. The major advantages of Halbach Arrays are that they can produce strong magnetic fields on one side whilst creating a very small stray field on the opposite side. This effect is best understood by observing the magnetic flux distribution.

• One-sided flux is useful in many applications – data security – transportation – motor design

• Halbach Arrays are inherently weight-efficient.

• Arrays provide higher fluxes than monolithic magnets of the same size.

Halbach array can be divided into ring arrays and linear arrays

Application:

• Optoelectronics, robot rotor and suction componentsFeatures:

• Powerful magnetic field with a small amount of magnets

• High adhesion and efficient assembly

• Equipped with magnetic field simulation design technology

-

Laminated Magnet for EV Cars

Application: Electrical vehicle drive motors, hub motors, rail transit motors

-

Electronic Devices

Application: Mobile phones, audio systems, headphones, etc.

-

Stator for Linear Motor

Application: Laser process equipment, IC chip manufacturing equipment, high precision machining equipment

-

Servo Motor Rotor Assembly

Application: Machine tool equipment, air conditioning equipment, automation equipment

Industry applications

WHY CHOOSE US

Professional magnetic material solution provider

It is a processor and technical service provider of rare earth permanent magnet core materials in electronics, military and other industries.

Wide coverage area

Targeting the global consumer electronics market, we integrate and provide innovative products and services for brand electronics enterprises through various development models such as self operated and cooperative operations

Numerous customers

Processing and technical service providers of rare earth permanent magnet core materials in industries such as electronics and military

R&D innovation

Research and develop more intellectual property products and technologies independently for magnetic materials.

Product inquiry